STEAMPUNK

Tallinn, Estonia

Winner of TAB2019 Installation Competition

2019.09

Design by:

Gwyllim Jahn & Cameron Newnham(Fologram),

Soomeen Hahm Design, Igor Pantic

Abstract

The structure is built from steam bent timber elements, using traditional crafting techniques and analogue tools augmented with the precision of holographic guides. The elements were prefabricated and assembled following holographic construction information viewed in augmented reality through Microsoft Hololens. Not a single construction drawing was produced in this process, which aims to expand the understanding of automated craft and production in the augmented age.⠀

Link

Dezeen

Archdaily

Designboom

ArchiPanic

C3DIZ

Estonia Architecture News

New Atlas

Parametric House

Awards

Estonia Wooden Buildings of the Year

Digital Futures Project Award

Idea-Tops Award 艾特奖

ArchDaily Building of the Year 2020 Awards Listed

Project Description

Steampunk is a pavilion constructed from steam-bent hardwood using primitive hand tools augmented with the precision of intelligent holographic guides. Designed by Gwyllim Jahn, Cameron Newnham (Fologram), Soomeen Hahm Design and Igor Pantic with Format Engineers, the installation was built for the 5th edition of Tallinn Architecture Biennale (TAB 2019) in Estonia, and will remain in place until the Biennale’s next edition in 2021.

As the designers of Steampunk we have not produced drawings or lines of CNC code from which parts of our design might be cut, printed or assembled and instead have developed an experimental approach to materialising architecture that serves as a deliberate polemic in the context of robotic production and automation. While computer aided manufacturing and robotics have given architects unprecedented control over the materialization of their designs, the nuance and subtlety commonly found in traditional craft practices is absent from the artefacts of robotic production because the intuition and understanding of the qualitative aspects of a project as well as the quantitative is difficult to describe in the deterministic and explicit language of these machines.

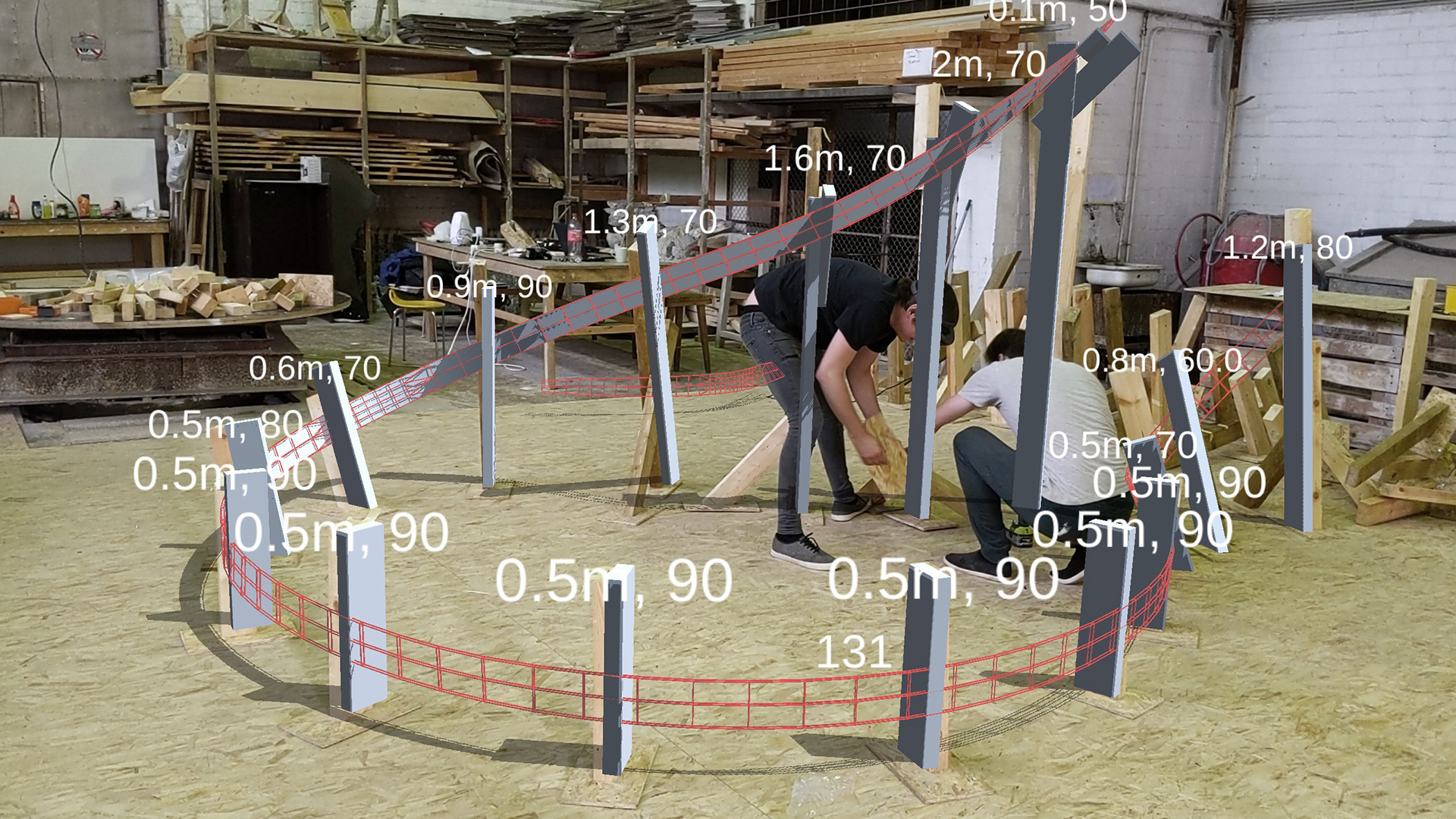

We are interested in approaches to making that hybridize analogue construction with the precision and flexibility of digital models. By rendering digital models as holographic overlays directly within construction environments, fabricators can use their own expertise and inventiveness to produce highly intricate and complex objects entirely by following these holographic guides using relatively primitive analogue tools. This approach removes the necessity of anticipating every aspect of material behaviour in digital models and in so doing leaves open a certain degree of indeterminacy as material affects are discovered, desired and amplified during construction. It is this liberation of digital expression from the constraints of digital fabrication, together with the opportunity for nuance and material affects derived from material craft, that drive the architectural effects of the pavilion.

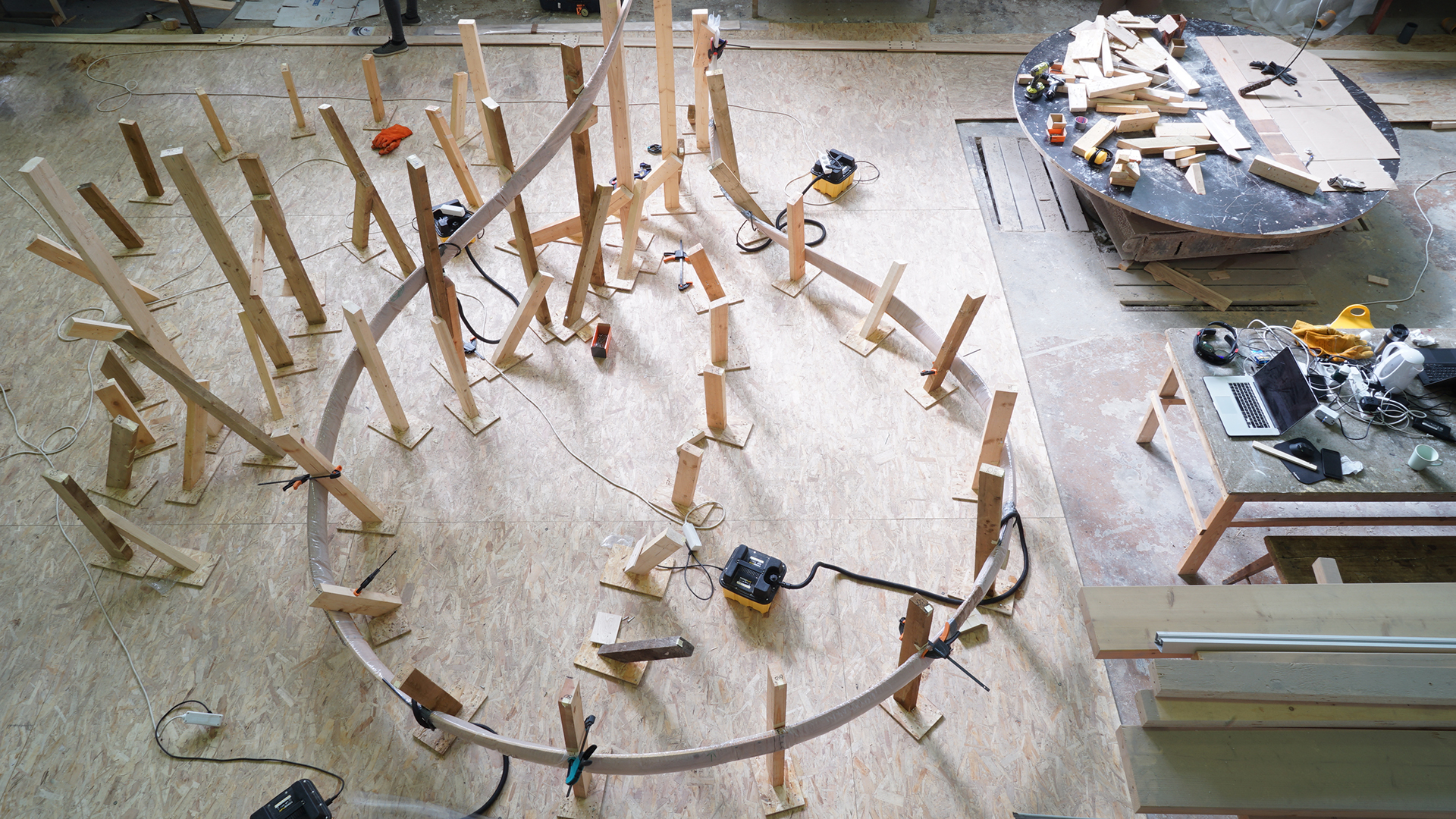

The plan of the pavilion is a cross that divides the grassy mound of the Biennial site into four distinct spaces that frame views towards the old city of Tallinn and the Architecture Museum. The variable surface effects in the pavilion are a product of expediency, as bending three dimensional curves from straight 100x10mm boards forces the timber profile to twist along its length. This attempt to produce an architecture from standardised lengths of material is more akin to weaving than assembling, and twisting timber sections contribute stiffness and compression strength to a composite timber and steel shell. Tracing the lines of the woven timber leads from conventional orthogonal surfaces to the complete break down of familiar topology, toying with the ambiguity of the form of the knot, inside and outside, surface and volume. In order to create a strong enough shell structure from light weight materials the pavilion also plays with positive and negative space, defining an intimate interior from a massive poche.

The timber elements in the structure are fabricated following the somewhat arcane and notoriously difficult process of steam bending. Each strip is bagged, steamed, and bent over an adaptable, moldless formwork using a holographic model as a reference to the desired result. This fabrication process utilizes two forms of feedback: holographic models provide fabricators with clear visual feedback on the accuracy of the forming process and allow them to intuitively adapt fabrication techniques or formwork positions until parts match digital models within accepted tolerances. Physical parts can also be digitized and fed back into the digital model, allowing the design to accomodate and adapt where necessary. In each case the feedback is a direct collaboration between designer and maker, between expected behaviour and observed results. The beauty of the project lies in this tension, in deciding when to give and take, when to adhere to preconceived design intent and when to abandon precision and begin to react.

Location : Ahtri 2, Tallin, Estonia

Size : 8.0m*8.0m*4.6m(w*d*h)

Area : 25m2

Completed : 11th September 2019

Project Team:

Sean Guy, Xavier Madden, Nick van den Berg, Hanjun Kim, Aishe Kokoshi, Triin Juhanson, Karim Rouabah, Szymon Padlewski, Thorlak Solberg, Christopher Ferris, Jack Mansfield-Hung, James Morton, Muhammad Ejle, Taivo Lints, Mathilde Grodem, Trine Jarsto, Bodil Eiterstraum, Gerda Levin, Simon Greil, Linn Johansson, Filip Nyborg, Anne Frydenlund, Arissara Reed, Haya Termanini, Mikkel Sorenson, Katrin-Maria Terras, Liis Aleksejeva, Annika Ülejõe, Kertu Jõeste, AnnaLiisa Saavaste, Helena Ojabstein, Lukas Winter, Philippe Hannequart, Kiheung Kwon, Katerina Konstantinidou, Tristan Krevald and Tom Morgan

Engineering:

Format Engineering, UK

Design:

Gwyllim Jahn, Cameron Newnham (Fologram, AU), Soomeen Hahm Design (UK), Igor Pantic (UK)

Photography: Peter Bennets, Hanjun Kim, Cameron Newnham